Chemical methods are one of the solutions used in wastewater treatment. At the same time, the use of polymers in liquids leads to agglomeration and accumulation of particles, which increases their density and ultimately leads to the stability of suspended particles. Polymers are widely used in various industries, including water and wastewater treatment, due to their macromolecular structure. Most polymers are powders and must be formulated through different preparation and synthesis processes. One of the most widely used polymers in the water treatment industry is polyelectrolytes, and the equipment that prepares and injects this chemical is called a polyelectrolyte pack.

Polyelectrolyte injection units are one of the most practical devices in the field of water and wastewater treatment and are used in the coagulation and flocculation stages of suspended solid particles in wastewater. Speeding up the process of preparing polyelectrolyte solutions and injecting them on demand based on the type of contaminants in water and wastewater are two of the main reasons for using injection kits and preparing polyelectrolyte solutions. Maharvin is an active manufacturer of equipment for the water and wastewater treatment industry, designing and producing polyelectrolyte injection kits of the highest quality. Below, we provide a complete introduction to this product .

What is a polyelectrolyte injection package?

The presence of suspended particles in industrial wastewater and treatment pond water and their inability to settle is one of the biggest problems during treatment and filtration. To this end, various methods such as aeration, injection of coagulants and flocculants have been proposed to solve these limitations. Polyelectrolyte is one of the most useful polymers in this field because it has a high molecular weight and is very effective at coagulating and flocculating suspended particles in water. Polyacrylamide or polyelectrolytes are available in anionic, cationic and uncharged types, depending on the type of molecules present in the water and wastewater. Since polyelectrolytes dissolve in hard water, devices called polyacrylamide injection packs are used. This kit is a set of components for high-speed preparation and injection of polyelectrolyte solutions .

Polyelectrolyte injection package parts

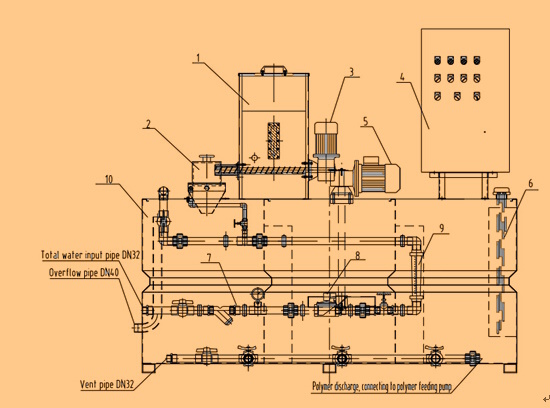

When designing and producing polyelectrolyte injection packaging, it is first necessary to pay attention to the conditions of the treatment plant and the type and quantity of wastewater, and correctly determine the size and dimensions of the packaging accordingly. Generally speaking, regardless of the size and capacity of the package, the device consists of several common parts, which are :

- Polyacrylamide powder receiving device

- Polyelectrolyte solution preparation device

- solution storage unit

- Polyelectrolyte injection device or metering pump

How these units are connected and what the package does is as follows :

First, polyelectrolyte powder enters the device or powder tank in a predetermined amount .

Depending on the amount of powder in the container, add water and use the mixer included in the package to obtain a homogeneous solution. Finally, the prepared solution is placed in the storage section, and under the required conditions, an appropriate amount is injected into the storage tank of the purification tank through a dosing pump or syringe pump. A very important point in the design and production of polyacrylamide injection packaging is to pay attention to the materials used for its body and other equipment contained within it. The device must be completely corrosion-resistant, and for this purpose it is usually made of stainless steel. To perform these operations, the following components and parts are used in the electrolyte injection package :

- polyacrylamide storage container

- Liquid or powder polyelectrolyte injection systems

- mixer

- Dilution tanks and solution storage

- Syringe or metering pump

- alarm system

- Electrical panels and PLCs

- Pipes and fittings, safety valves, injectors and …

There are different types of syringe pumps used in this package depending on the type of device application, the amount of solution required for injection, and other factors. For example, the most common metering pump types in this kit are diaphragm pumps and pneumatic pumps .

What are the uses of polyelectrolyte injection?

As mentioned earlier, polyelectrolytes are among the most useful polymers for coagulating and flocculating suspended particles in water and wastewater. Therefore, it can be used in different environments, some of them are :

- water purification and filtration

- Removal of suspended matter from wastewater and industrial water

- Treatment of wastewater from refineries and petrochemical plants

- Use of polyelectrolytes for color removal in dyeing and petrochemical plants

- Improve agricultural water absorption coefficient

- Purify water entering ventilation and cooling systems

- Removal of colloidal particles from steel industry wastewater

Advantages of using polyelectrolyte injection packages

The wide application of polyelectrolyte injection packages demonstrates the many advantages and high efficiency of this equipment. The most important advantages of using this kit for injecting polyacrylamide solutions are as follows :

- Easy to operate in a short time

- It can be designed in a fully automatic manner to inject the appropriate amount of solution at the specified time without manual operation.

- Does not require much space for placement and installation

- Very efficient preparation and injection of coagulation solutions

- Fully continuous production of uniformly concentrated polyelectrolyte solutions 24 hours a day

- No maintenance required

- Body fully resistant to impact and contact with corrosive materials

- They can be designed in different sizes and dimensions and adapted to the required environmental conditions

Buy Polyelectrolyte Injection Packs

Purchasing polyelectrolyte injection is a necessary task in various industries due to its advantages. A very important thing when purchasing this pack is to pay attention to its size, dimensions and capacity . In other words, before purchasing a polyelectrolyte injection package, one needs to consider the conditions of the treatment plant and proceed with the design and production phases accordingly. Maharvin Group considers the required refinery and industry conditions, weighs various design factors and designs and produces to the highest quality. To get in touch you can use the communication options mentioned at the bottom of the page